|

Download:

|

Integrated and Embedded Kinematic Mounts

Our patented BiCollar technology lends itself easily to direct embedding into third-party products, bypassing the need for the bolt-in base blocks of the MKM product line, reducing stack height by more than 50%, eliminating the most complex components and lowering costs significantly.

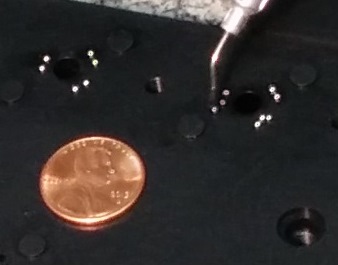

This is very appealing for small interfaces, where the size of standard fasteners becomes a limiting factor. In these pictures we show part of an embedded BiCollar mount used for repeatable positioning in an electro-optical manufacturing application. The balls are 1 mm in diameter, and the carrying capcity is over 10 kg, used to ensure adequate clamping forces. Being kinematic, the mount remains fully defined and repeatable even as the assembly goes in and out of different thermal environments. Integrated mounts can also be used to interface directly with manufactured objects by having 3 conical depressions formed or machined into them, as in the case of holding cast objects.

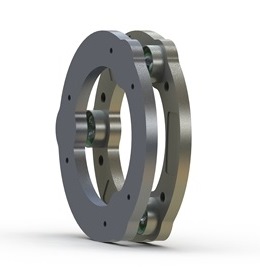

Similarly, we can provide complete custom Integrated Kinematic Mount interfaces, which are complete matching mating-plate pairs that already embed all three (or four) mating elements, and provide a bolt-in interface for the entire mount (Instead of for each individual mating element), again reducing stack height, part count, and cost.

We can provide interface plates that are round or rectangular, per your specification, from centimeter to meter scale. Integrated Kinematic Mounts can be useful, for example, in robotic applications, for quick registration and location of end effectors into work stations, repeatable tool pick up, and similar tasks. Integrated Kinematic Mounts can be complemented with feed-through quick connects of verious types, as well as magnetic or mechanical clamps according to your specifications. EKM and IKM designs are application-specific - contact us to discuss using them in your products. Please contact us with any questions,

by email at

, or by phone at

|

| 650-605-4500 | ©2017 g2-engineering |