|

Kinematic Mount Technology Comparison

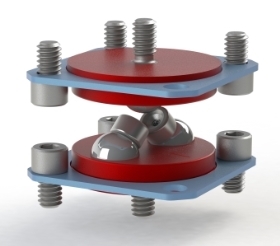

Contact and Motion Geometries The Spherolinder acheives a 1-DOF motion by sliding a cylindrical surface in a V-groove, whereas the BiCollar achieves it by combining two ball-in-cone rotations The ball-in-cone mechanics are superior, but the resultant 1-DOF motion is not a top-of-arc, not a planar straight line. This is the basic trade-off between the two designs. Load Capacity Both product families, Spherolinders and BiCollars, offer roughly comparable load capacity for a given footprint - 2 tons over a ~1.5" diameter base (SPH-M25 or BC0500). This recommended load is for horizontal and static assemblies, and is just under 50% of the calculated yield load for the Herzian contact elements. For tip-tilt and dynamic loads, the retention pre-load must be calculated in. Care must be taken not to exceed the load limit during assembly. OTx products are designed only for horizontal static loads. In all cases, load may be limited by the taps for the bolt-down bolts. For both mounts, load capacity scales with the square of the spherical diameter, so the SPH-M50 and the BC1000 are good for four times as much load, or 8 tons, per mount point. Bolt-Through Geometry The Spherolinder uses a single central stud, fixed in place, perpendicular to the plane. The top component is clamped using a set of beleville washers, which give it compliance. The BiColar mount uses two parallel studs that can rotate to remain along the line-of-force. The top component is clamped using a large beleville washer, but additional spherical nut allow for all motions without relying on spring compliance. Stiction and Fatigue Life The sphere-in-cone rotation used by the BiCollar is a better movement compared with the cylinder-in-groove sliding used by the Spherolinder, since there is no “leading edge” to the movement. Additionally, the BC0500 uses simple ground Spheres, which have very high Sphericity and very good surface smoothness. The reduced stiction manifests itself in lower residual stresses, and therefore inproved repeatability. An immediate result of reduced stiction is improved fatigue life. Part Count, material The Spherolinder is a simpler device that uses large components and is 100% stainless steel. The BiCollar mount is a bit more complex, and has a polymer retainer seal. The OTx version uses Aluminum baseplates and clamp plates. The Spherolinder naturally has no trapped volumes, and so is better suited for high-vacuum applications. The BiCollar mount can be adapted to high vaccuum service by adding vent channels. Flatless cone-groove-flat The regular 3-legged mount uses the "2-2-2" kinematic configuration, which is symmetrical, and uses 3 groove elements. The MKM and OTx mounts also feature a "3-2-1" kinematic configuration, also known as a "cone-groove-flat". In our version of the mount, we replace the "flat" mount point with a vertical 1-DOF bicollar element that functions in a pretty similar way, but is not alignment-sensitive like other flat mount points. 4-legged mount MKM and OTx mounts also allow "2-2-1-1" kinematic configuration, which is suitable for rigid rectangular frames. Click here for general information on 4-legged mounts. Embedded mounts BiCollar mounts can be embedded directly into your product by integrating the baseplates into your components. Contact us for more details. Modular Kinematic Mount Part Catalog

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 650-605-4500 | ©2017 g2-engineering |